Service hotline:

Zero discharge of electroplating waste gas

Surfatech Chemistry Technology has been involved in the design and manufacture of electroplating waste gas treatment processes and equipment since 2010, and has successively developed hexavalent chromium-containing electroplating waste gas treatment systems, cyanide-containing electroplating waste gas treatment systems, integrated electroplating waste gas treatment systems, and NxOy yellow smoke-containing electroplating waste gas treatment systems. System, organic waste gas treatment system, etc., formed a complete set of electroplating waste gas zero emission technical solutions from program design, treatment agent R&D and production, equipment manufacturing and installation to emission quality monitoring.

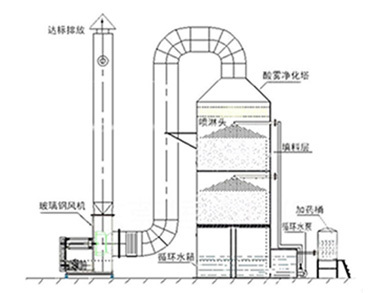

Single tower spray type electroplating waste gas treatment system

Surfatech Chemistry Technology®Four major advantages of electroplating exhaust gas zero emission solutions:

One of the advantages: has a number of patents and proprietary technologies

Advantage 2: Customized according to electroplating process and production line conditions

Advantage three: low operating cost

Advantage 4: Years of design experience, one-stop service

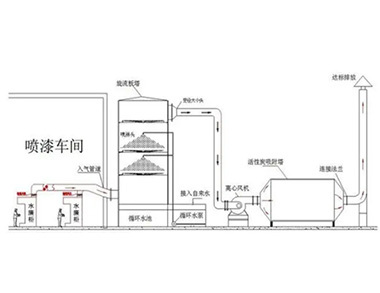

Organic waste gas treatment system

Surfatech Chemistry Technology®Three reasons for the zero discharge solution of electroplating waste gas:

Reason 1: the need for green electroplating

Reason 2: The need to reduce the cost of electricity

Reason 3: The need to improve the quality of electroplating

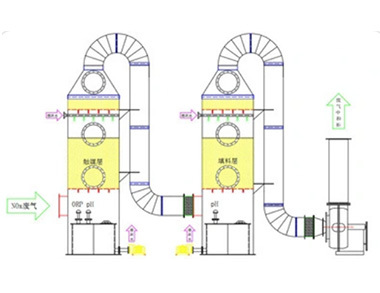

Nitric acid yellow smoke exhaust gas treatment system

Business Process:

Step 1: determine the intention of cooperation

Step 2: Customize technical solutions

Step 3:Sign the supply contract

Step 4:Equipment installation and commissioning

Step 5:Equipment acceptance and delivery

Step 6:After-sales service

客服热线:

客服热线: